| .. | ||

| .gitignore | ||

| build.sh | ||

| config.h | ||

| keymap.c | ||

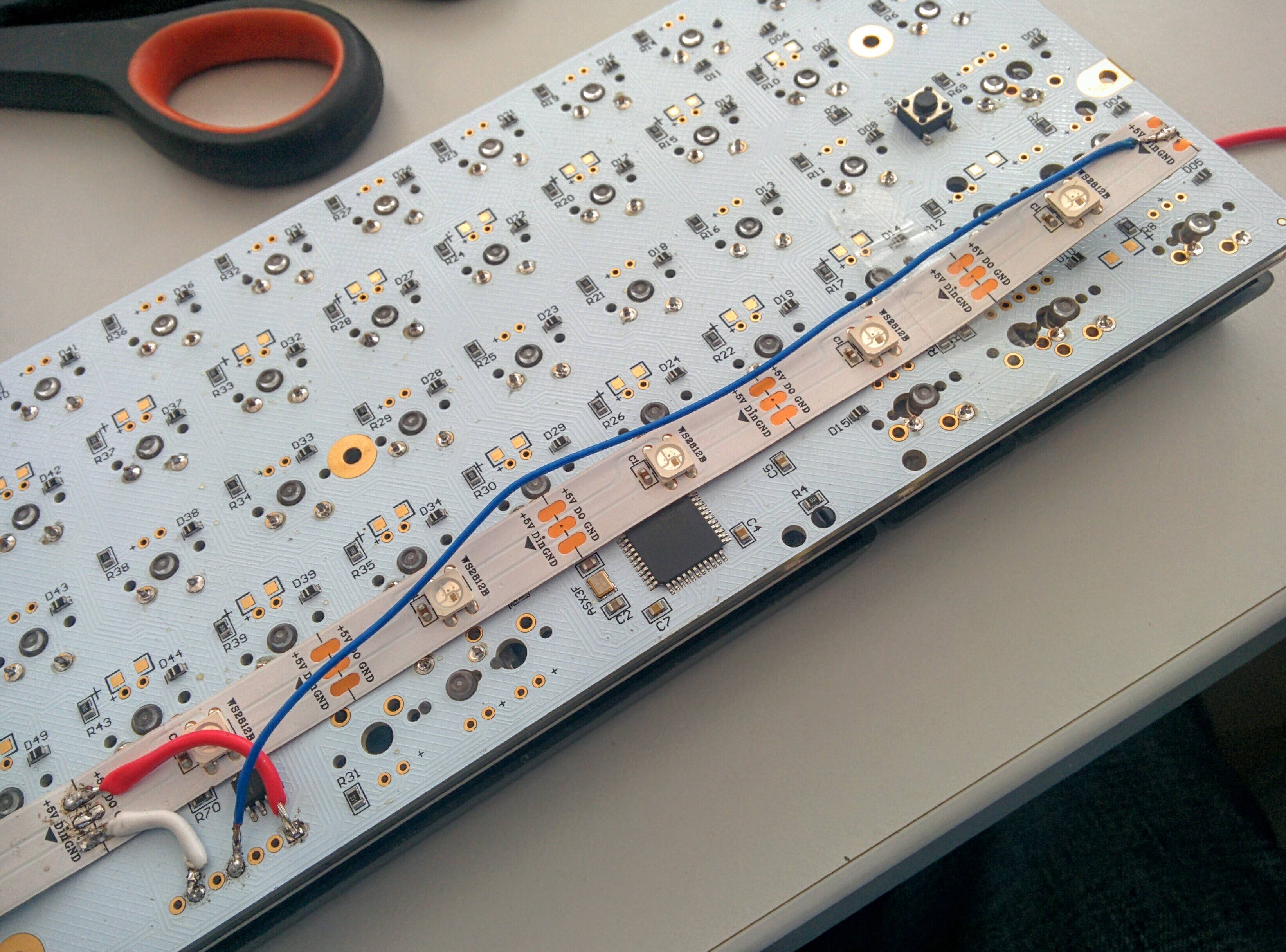

| LEDpinSatan.jpg | ||

| Makefile | ||

| readme.md | ||

| resetboard.sh | ||

| satan.c | ||

| satan.h | ||

toneman77's Satan Layout

##Quantum MK Firmware For the full Quantum feature list, see the parent readme.md.

- heavily modified ISO (!) layout with split right shift key

- spaceFn

- Dual-Role keys:

| Original key | when tapped | when held |

|---|---|---|

| Space | Space | layer change |

| Caps lock | Escape | Control |

| Tab | Tab | layer change |

| Enter | Enter | Control |

- Lockable layer for LED functions and numpad

- vim-style arrow keys on hjkl (spacefn layer)

- corresponding Home/PgDn/PgUp/End on hjkl (tab layer)

- bonus arrow keys in the bottom right corner on Alt/Win/Menu/rCtrl/Shift

- more bonus arrow keys on wasd (spacefn layer)

- media keys prev/next/play/vol+/vol- (spacefn layer)

- formware bootloader button

- WS2812 RGB Underglow Support (not needed anymore to solder directly to the atmega)

- additional brackets that only work in german layout due to horrible placement in the default qwertz layout